(This is an abstract of my LinkedIn newsletter, “Food in the Spotlight“)

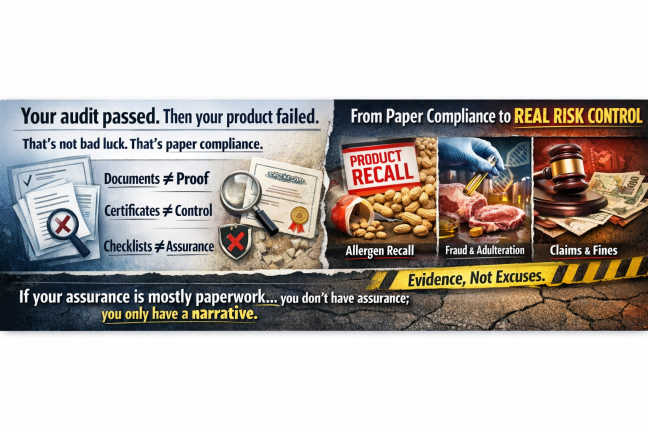

Your audit passed. Then your product failed.

That’s not bad luck. That’s paper compliance.

In food, the most expensive surprises happen when organisations confuse:

- documents with proof

- certificates with control

- checklists with assurance

Three areas where this gap escalates fast:

- Allergens: a label swap. A line mix-up. A GMP drift. A “may contain” used as a safety blanket. Soon after that: injury, recall, headlines, litigation.

- Authenticity/Fraud: a new overseas supplier, a nice price, and a generic “EU/market suitable” declaration, plus one well-packaged shiny lab analysis. “We’re covered”. Until a major consignment is blocked at the border or recalled, because outsourcing the burden of proof was never designed to detect drift or adulteration.

- Claims/Composition (especially across different jurisdictions): a claim that is acceptable in one market becomes unlawful in another, or simply borderline and challenged in Courts under local interpretation of the rules. An additive or a new fancy clean ingredient that is ruling one market might be banned or need pre-market authorization in another. The results? fines, re-labelling, retailer escalation, reputational damage.

I can go on with the list. But here’s the uncomfortable truth: the comedy played by all parties on the audit day is not risk management.

The gold standard should be evidence-based, risk-driven surveillance:

- build a food safety culture: your people are your eyes and ears;

- rank risks (by commodity, origin, trade lanes, historical incidents, internal failures);

- build targeted proof (testing strategy, sampling, chain-of-custody);

- invest only where risks hit harder and can be effectively reduced to an acceptable level (methods, traceability, technology): we cannot prevent all the “unknown unknowns”, and for some “known unknowns” we might not have the right technology;

- set triggers and governance (what changes when early risk signals appear).

𝑰𝒇 𝒚𝒐𝒖𝒓 𝒂𝒔𝒔𝒖𝒓𝒂𝒏𝒄𝒆 𝒑𝒓𝒐𝒈𝒓𝒂𝒎𝒎𝒆 𝒊𝒔 𝒎𝒐𝒔𝒕𝒍𝒚 𝒑𝒂𝒑𝒆𝒓𝒘𝒐𝒓𝒌, 𝒚𝒐𝒖 𝒅𝒐𝒏’𝒕 𝒉𝒂𝒗𝒆 𝒂𝒔𝒔𝒖𝒓𝒂𝒏𝒄𝒆; 𝒚𝒐𝒖 𝒐𝒏𝒍𝒚 𝒉𝒂𝒗𝒆 𝒂 𝒏𝒂𝒓𝒓𝒂𝒕𝒊𝒗𝒆.

A narrative, now AI-powered and fueled by cost saving and head cuts that drain skills and experience from companies, and most of the time supported by two powerful and devious statements:

“𝘌𝘷𝘦𝘳𝘺𝘣𝘰𝘥𝘺 𝘪𝘴 𝘥𝘰𝘪𝘯𝘨 𝘭𝘪𝘬𝘦 𝘵𝘩𝘪𝘴.”

“𝘞𝘦 𝘢𝘭𝘸𝘢𝘺𝘴 𝘥𝘪𝘥 𝘪𝘵 𝘵𝘩𝘪𝘴 𝘸𝘢𝘺.”

Yes, indeed.

That is exactly why you hire a consultant. At least a real one, not a “talking suit”.

The “talking suit” effectiveness stands to Mr. Wolf (do you remember Pulp Fiction?) as paper compliance stands to risk-based surveillance.

I recently hit this nail in several LinkedIn posts, and I do not plan to stop or sugarcoat it. Check in particular:

- 𝐓𝐡𝐞 𝐄𝐧𝐝 𝐨𝐟 “𝐉𝐮𝐬𝐭-𝐢𝐧-𝐂𝐚𝐬𝐞” 𝐀𝐥𝐥𝐞𝐫𝐠𝐞𝐧 𝐋𝐚𝐛𝐞𝐥𝐢𝐧𝐠 𝐟𝐨𝐫 𝐌𝐮𝐬𝐭𝐚𝐫𝐝? Educative read about analytical uncertainty, allergen risk, and the misuse of precautionary allergen labeling.

- 𝐄𝐅𝐒𝐀 – 𝐏𝐞𝐬𝐭𝐢𝐜𝐢𝐝𝐞 𝐫𝐞𝐬𝐢𝐝𝐮𝐞𝐬 𝐢𝐧 𝐟𝐨𝐨𝐝: 𝐭𝐡𝐞 𝐪𝐮𝐢𝐞𝐭 𝐢𝐥𝐥𝐮𝐬𝐢𝐨𝐧 𝐨𝐟 𝐬𝐚𝐟𝐞𝐭𝐲 About why a 98-99% compliance rate is not necessarily equal to safety assurance, the uneven distribution of risk and the fallacy of statistics. Suggested non-food reading: “The Black Swan: The Impact of the Highly Improbable” by N. N. Taleb. This will change the way you look at numbers and graphs every time.

- 𝐅𝐨𝐫𝐞𝐢𝐠𝐧 𝐛𝐨𝐝𝐢𝐞𝐬 𝐢𝐧 𝐟𝐨𝐨𝐝 𝐚𝐫𝐞𝐧’𝐭 𝐣𝐮𝐬𝐭 𝐚 𝐬𝐚𝐟𝐞𝐭𝐲 𝐫𝐢𝐬𝐤; 𝐭𝐡𝐞𝐲 𝐚𝐫𝐞 𝐚 𝐫𝐞𝐩𝐮𝐭𝐚𝐭𝐢𝐨𝐧 𝐤𝐢𝐥𝐥𝐞𝐫, as the title implies.

Next week, you will find me in London, at BRCGS Connect Europe 2026, with a speech on emerging risks for food supply chains. Come and say hello.

And do not forget our 3-part webinar series about food labeling is approaching. There is still time to register. For more details, check here.

Stay tuned, stay compliant, and keep the food in the spotlight.

Discover more from FOOD LAW LATEST

Subscribe to get the latest posts sent to your email.